Booking Information

X-ray photoelectron spectroscopy (XPS), also known as ESCA (Electron Spectroscopy for Chemical Analysis), is used to analyze the surface chemistry of a solid material.

The material can be a powder (e.g., nanomaterials) or a film (organic polymers, inorganic compounds, paints, ink etc.) deposit on a gold substrate, glass or on a Si wafer. XPS utilizes the photoelectric effect.

Book Instrumentation Time

- Academic users, who prefer to measure their own samples, must first arrange for training by contacting our Instrument Facilities Manager.

- Upon successful completion, the user can send a request for time on the XPS to the Instrument Facilities Manager who will then assign the time slot in conjunction with the user.

- Only trained users will be allowed to book time on the instrument and to operate it independently.

- All users will indicate their understanding of the basic safety and operational procedures of the equipment by signing the Safety Certification Sheet.

Friday overnight and weekend sessions are available to fully trained, experienced users only!

Submit Samples for Processing

Academic and non-academic users, who would like to have their samples processed by a staff member of the Surface Analysis Facility, should contact the Instrument Facilities Manager directly and should submit a Request Form for XPS Measurements.

Typical Analysis Times:

Acquisition times for survey scans: 3 - 4 minutes.

Acquisition times for high resolution scans: 5 minutes to 1.5 h per element region (C1s, O1s etc.) depending on the abundance of the element in question.

Almost any material can be analyzed with the XPS as long as several conditions are met:

- Samples must be ultra high vacuum compatible (< 10-8 torr). Most samples take at least 2 hours to pump down from atmospheric pressure, before they can be transferred into the UHV environment of the XPS system; powdered samples may take longer. For that reason, samples should be submitted the day before the measurement, so staff members can start a pump down on these samples overnight. Users, who are are measuring their samples themselves, are required to co-ordinate with any other users on the day prior to their measurement the pump down of their samples overnight. In doing so, this would not only expedite transfer of samples to and from the analysis chamber and would ensure that the UHV environment is not compromised.

- It is recommended to dry the sample in a desiccator or under vacuum (preferred) and to store the sample under nitrogen or argon prior to analysis. Following this procedure will remove any volatile materials adsorbed by the sample.

- The sample stage can fit up to 3 samples of 0.5 - 1 cm2 in size. The maximum sample width is ca.1.2 cm.

- For samples deposit on Si wafers or gold substrates, a smooth surface of at least 5 mm² should available for analysis. For powdered samples, enough material should be submitted to cover an area of least 5 mm2 (ca. 0.2 g).

- The sample stage can fit up to 3 samples of 0.5 to 1 cm2 in size. The maximum 1sample width is ca.1.2 cm. Samples are being mounted using conducting Cu tape onto an aluminium stub.

- Non-conducting samples for XPS analysis should be as thin as possible so as to minimize charging effects.

Internal Users:

- samples run by a trained user: $15 per hour

- samples run by the Instrument Facilities Manager: $20 per hour

External Academic Users:

- samples run by a trained user: $15 per hour

- samples run by the Instrument Facilities Manager: $20 per hour

Industrial Users:

- samples run by the Instrument Facilities Manager: $60 per hour

Samples will be disposed of 30 days after completion of the analyses, unless the return of the samples is requested on the Request Form. Sample return costs will be added to your invoice unless a courier account number (FedEx or DHL) is provided.

How XPS Works

In a typical experiment, the material is irradiated with soft X-rays (Al-Kα or Mg-Kα) resulting in photoelectrons with the energy hn to be emitted from the top surface layer (1 to 5 nm) of the solid material. The emitted photoelectron has a characteristic kinetic energy (KE), which is converted to the binding energy (BE) of the electron:

KE = hν - BE - Φ

Φ is so called work function of the instrument.

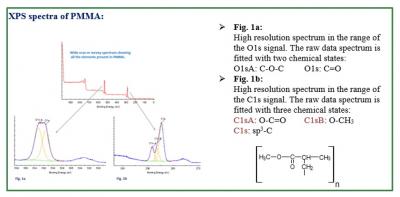

The characteristic binding energies for each element within the PSE are known and are used to identify the elements present on the surface of the sample. However, only elements with an atomic number Z > 3 (lithium) can be detected. The values for binding energies and the intensities of the photoelectron peaks provide information about the identity and quantity of the elements present and their chemical state. As an example the XPS spectrum of polymethylmeth-acrylate (PMMA) is shown below:

| Address

Department of Chemistry |

Phone

Office: 613-533-6000 ext. 74474 |

Hours

Monday to Friday |

Contact Information

Dr. Gabriele Schatte

Instrumentation Manager

Email: gabriele.schatte@chem.queensu.ca